About us

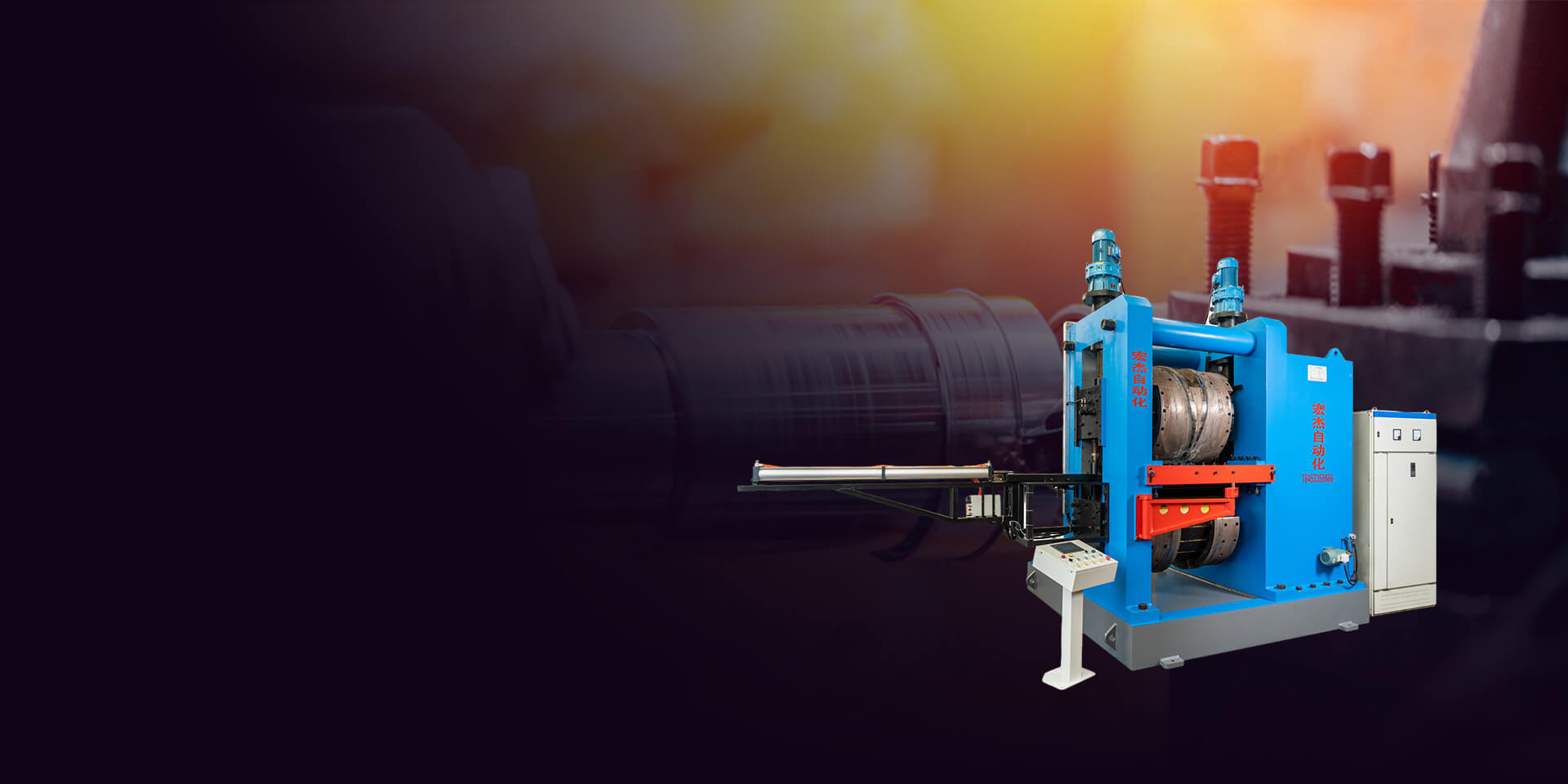

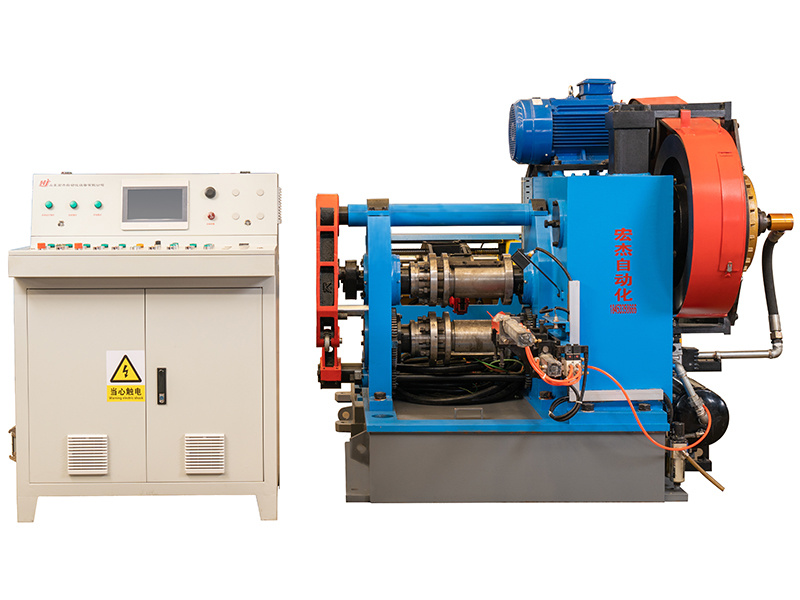

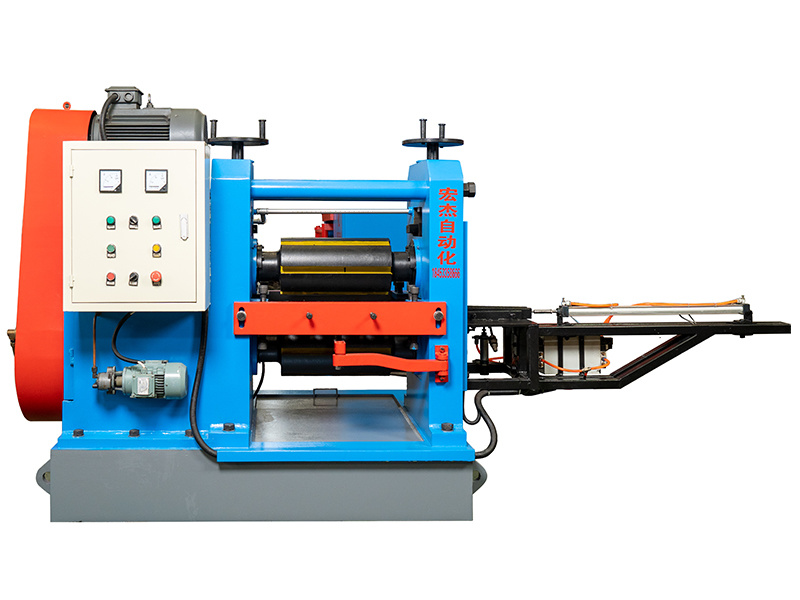

Zibo Hongjie Forging Industry Equipment Co., Ltd. is a leading manufacturer of advanced forging equipment to industries around the world. We specialize in design, manufacture, and sale of cross wedge rolling machines, roll forging machines, and other support equipment. 30 years of technical expertise enable us to understand the key to successful forging industry, provide a range of forging machines and comprehensive customized solution to streamline your forging process and integrate seamlessly with your existing workflows.

Explore MoreSolution

Tailored solutions for all your forging requirements and optimizing production processes.

Product

Roll forging machines and Cross wedge rolling machines, maximize efficiency and minimize costs.

Free Consultation

Our experts are ready to help, taking your forging productions to the next level.

Forging Piece Display

Related Equipment

Customized Service

We provide customized solutions to meet the unique demands of each industry we serve. We offer more than just machinery equipment. We’re also capable to make customized toolings and 3D prototypes, reverse engineering, and precision machining

Agricultural

Construction

Automative

Truck/Trailer

Ordnance

Marine

Hardware/Tools

Mining

Railroad

COMMON QUESTIONS

Most Popular Questions.

You may have questions about our products and how they can benefit your business. Here’s a list of FAQs about our roll forging machine, cross wedge rolling machine, and bucket teeth for excavators. Don’t see your question? Contact us and we’ll be happy to help!

-

What is the main difference between roll forging machines and air hammers?

Roll forging machines use two or more rollers to apply force to a workpiece, while air hammers use compressed air to strike the workpiece. Roll forging is ideal for producing long parts, while air hammers are better suited for shaping smaller parts.

-

What is the advantages of roll forging machine comparing with air hammer?

Higher production efficiency: Roll forging machines can produce parts at a faster rate than air hammers, as they work continuously and can produce a higher volume of parts per hour. Consistent quality: Roll forging machines can provide a more consistent product quality as they maintain a consistent pressure throughout the forging process, whereas air hammers rely on the operator's skill and experience. Better material utilization: Roll forging machines can achieve a higher material utilization rate, which means less waste and lower material costs. This is because roll forging can produce parts with a higher length-to-diameter ratio, resulting in more efficient use of the material. Greater versatility: Roll forging machines can be used to produce a wider range of parts and shapes than air hammers, due to their ability to use different types of dies and tooling. This makes them a more versatile choice for many forging applications.

-

What is the main difference between roll forging machine and cross wedge rolling machine?

Roll forging machines use two or more cylindrical rolls to apply pressure and shape the metal while cross wedge rolling machines use a wedge-shaped tool to deform the metal. Cross wedge rolling machines are better suited for producing complex shapes due to the wedge-shaped tool which allows for more intricate deformations, while Roll forging machines are generally more cost-effective for large-scale production due to their higher production capacity and faster forging speed.

-

Can you make comprehensive solution of forgings production?

Yes, we can design and manufacture customized forging dies according to your specific product requirements, and provide a specific solution for your forgings production, which includes the necessary equipment, forging mould and training for you to produce the parts in-house. However, it's important to note that forging is a specialized manufacturing process that requires knowledge and expertise to ensure high-quality results. Please mail us for more details.

-

What are the factors that affect the quality of bucket teeth for excavators?

The quality of bucket teeth for excavators can be affected by factors such as the material used, the manufacturing process, the design of the tooth, and the wear resistance of the tooth. The frequency of bucket teeth replacement depends on factors such as the type of material being excavated, the hardness of the ground, and the frequency of use. However, as a general rule, bucket teeth should be replaced when they have worn down to about 50% of their original size.